Seit 1972 am Markt, hat sich das dk-Team schon früh mit Fixiertechnologien beschäftigt – und im Laufe der Zeit dieses Produktspektrum weiter entwickelt. Heute umfasst das Sortiment ca. 1.000 Produkte, die frei kombinierbar sind und somit ein Baukasten-System bilden.

Anwender, die mit dk-Technik arbeiten, bestätigen uns regelmäßig:

Flexible Kombinationsmöglichkeit der Module sowie Langlebigkeit der

Elemente garantieren ein präzises Messergebnis bei zügigem Workflow.

FAST.

REASSEMBLY.

LIFELONG.

Das Grundprinzip aller dk Fixiersysteme.

Unsere Vorrichtungen sind modular konzipiert,

jederzeit rückbaubar und lassen sich identisch

wieder neu zusammensetzen.

Durch die Kompatibilität der dk Fixiersysteme

wird der Nutzwert perfekt.

Unsere Vorrichtungen sind modular konzipiert,

jederzeitrückbaubar und lassen sich identisch

wieder neu zusammensetzen.

Durch die Kompatibilität der dk Fixiersysteme

wird der Nutzwert perfekt.

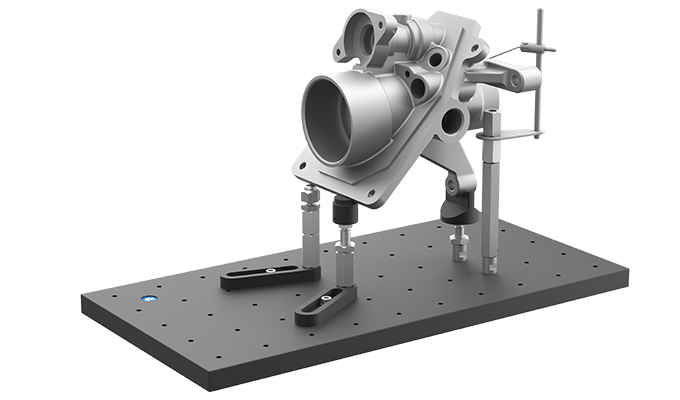

Anwendung vorwiegend auf mittleren bis großen Koordinatenmessgeräten (KMG) für die dimensionelle Werkstückprüfung.

Die infolge großer Auswahl von Bauteilen individuell und anforderungsgerecht konfigurierbare Vorrichtung hält den Prüfling sicher und wiederholgenau. Dabei ist sie platzsparend, um den Prüfling maximal zugänglich zu machen.

Modulsystem geeignet für 1-malige Messungen (Bsp. Prototypen, Losgröße 1 und Kleinstserien) durch schnellen Aufbau und Rückbau.

Modulsystem geeignet für Serienmessungen (wiederkehrende größere Produktionsmengen) mit wiederholgenauer Positionierung der Prüflinge und reproduzierbarem Gesamtaufbau der Spannvorrichtung.

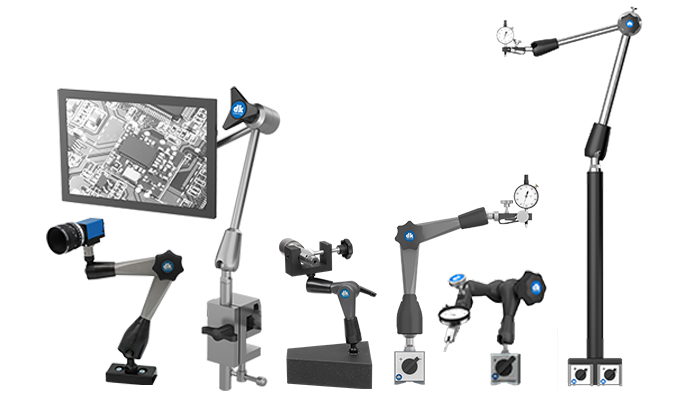

Anwendung auf kleineren bis mittleren taktilen Messmaschinen und Multisensorgeräten.

Die infolge großer Auswahl von Bauteilen individuell und anforderungsgerecht konfigurierbare Vorrichtung hält den Prüfling sicher und wiederholgenau. Dabei ist sie platzsparend, um den Prüfling maximal zugänglich zu machen.

Modulsystem geeignet für 1-malige Messungen (Bsp. Prototypen, Losgröße 1 und Kleinstserien) durch schnellen Aufbau und Rückbau.

Modulsystem geeignet für Serienmessungen (wiederkehrende größere Produktionsmengen) durch wiederholgenaue Positionierung der Prüflinge und reproduzierbaren Gesamtaufbau der Spannvorrichtung.

Anwendung auf optischen Koordinaten-Messsystemen, Multisensor-Messmaschinen, digitalen Messprojektoren und Digitalmikroskopen.

Die infolge großer Auswahl von Bauteilen individuell und anforderungsgerecht konfigurierbare Vorrichtung hält den Prüfling sicher und wiederholgenau. Dabei ist sie platzsparend, um den Prüfling maximal zugänglich zu machen.

Modulsystem geeignet für 1-malige Messungen (Bsp. Prototypen, Losgröße 1 und Kleinstserien) durch schnellen Aufbau und Rückbau.

Modulsystem geeignet für Serienmessungen (wiederkehrende größere Produktionsmengen) durch wiederholgenaue Positionierung der Prüflinge und reproduzierbaren Gesamtaufbau der Spannvorrichtung.

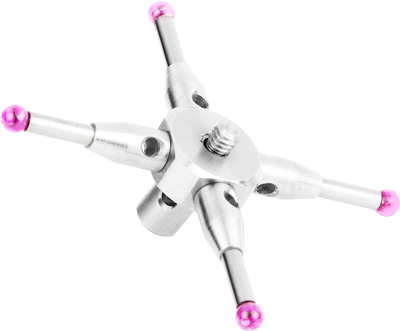

Anwendung auf taktilen und optischen Kontur-/ Form- und Rauheitsmessgeräten.

Die infolge großer Auswahl von Bauteilen individuell und anforderungsgerecht konfigurierbare Vorrichtung hält den Prüfling sicher und wiederholgenau. Dabei ist sie platzsparend, um den Prüfling maximal zugänglich zu machen.

Modulsystem geeignet für 1-malige Messungen (Bsp. Prototypen, Losgröße 1 und Kleinstserien) durch schnellen Aufbau und Rückbau.

Modulsystem geeignet für Serienmessungen (wiederkehrende größere Produktionsmengen) durch wiederholgenaue Positionierung der Prüflinge und reproduzierbaren Gesamtaufbau der Spannvorrichtung.

Anwendung auf taktilen und optischen Kontur-/ Form- und Rauheitsmessgeräten.

Die infolge großer Auswahl von Bauteilen individuell und anforderungsgerecht konfigurierbare Vorrichtung hält den Prüfling sicher und wiederholgenau. Dabei ist sie platzsparend, um den Prüfling maximal zugänglich zu machen.

Modulsystem geeignet für 1-malige Messungen (Bsp. Prototypen, Losgröße 1 und Kleinstserien) durch schnellen Aufbau und Rückbau.

Modulsystem geeignet für Serienmessungen (wiederkehrende größere Produktionsmengen) durch wiederholgenaue Positionierung der Prüflinge und reproduzierbaren Gesamtaufbau der Spannvorrichtung.

Anwendung auf taktilen und optischen Kontur-/ Form- und Rauheitsmessgeräten.

Die infolge großer Auswahl von Bauteilen individuell und anforderungsgerecht konfigurierbare Vorrichtung hält den Prüfling sicher und wiederholgenau. Dabei ist sie platzsparend, um den Prüfling maximal zugänglich zu machen.

Modulsystem geeignet für 1-malige Messungen (Bsp. Prototypen, Losgröße 1 und Kleinstserien) durch schnellen Aufbau und Rückbau.

Modulsystem geeignet für Serienmessungen (wiederkehrende größere Produktionsmengen) durch wiederholgenaue Positionierung der Prüflinge und reproduzierbaren Gesamtaufbau der Spannvorrichtung.

Anwendung in allen Bereichen der industriellen Bildverarbeitung sowie der berührungslosen Mess- und Prüftechnik, insbesondere der Inline-Messtechnik.

Für die Montage und Positionierung von Kameras, Sensoren, Beleuchtung, End-Of-Arm-Robotertools uvm.

Die infolge großer Auswahl von Bauteilen individuell konfigurierbaren Modulsysteme sind geeignet sowohl für die Projektierung (Proof of Concept) als auch ganz besonders für den harten industriellen Einsatz (Field Application).

Für jede Beanspruchung des jeweiligen Einsatzgebiets gibt es anforderungsgerechte Programme, die auch untereinander kombinierbar sind.

Sie sind hier: → Zur Anwendung zusammen mit Robotern im Umfeld von KMG’s, optischen Messmaschinen, Computertomographen, Oberfläche- & Konturmessgeräten sowie 3D-Scanning-Systemen. Optimierung der gesamten Prozesskette » Perfekte Integration der Messmaschine in den Gesamtprozess» Geordnete Bereitstellung der Prüflinge an der Messmaschine»

Anmeldung